With 3D software and CNC equipment, we can provide the initial prototype quickly, so our customers can easily and intuitively check their designs.

At the same time, we choose high – precision 3D printer and silicone mold to make copies in small batches which can reduce the cost and shorten production time. It has a great influence that customers can test and display the prototypes before tooling, lower marketing cost and offer chance to modify in time.

We accumulated extensive experience in developing and producing popular board games. If you have any problems about development, please do not hesitate to contact us. Our suggestions may help you save time and cost, even give you a burst of inspiration.

Original design has large space for improvement. Starry Games can modify and improve the miniature according to the game rule, function and customer’s budget, make the game more perfect.

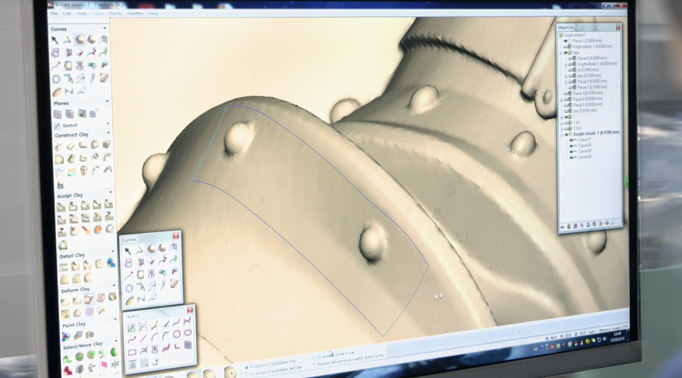

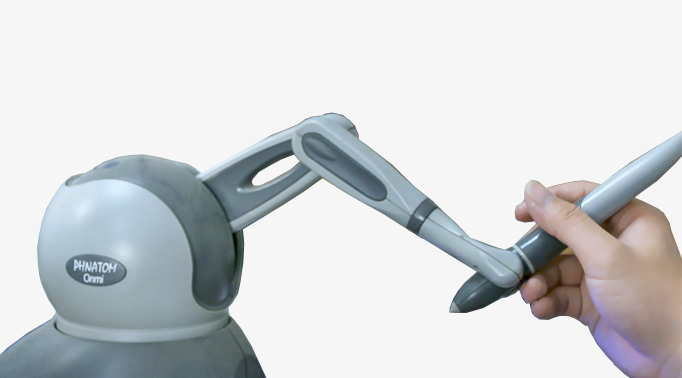

Starry Games’ technicians are skilled in using FreeForm and Zbursh software, we can help customers build the 3D mold quickly base on the customer’s concept and graphic design.

Base on customer‘s STL file, we can make 3D printing prototype for customer’s approval.

When you have creativity in mind, Starry Games can submit the physical prototype for customer to test and improve the product function.

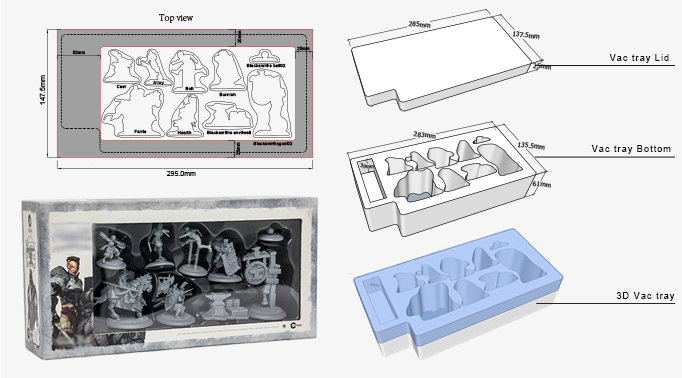

We can submit the mock up white sample for customers to test the materials, size, structure and quantity if suitable for the game. What‘s more, we can use the digital printing machine and CAD Table to make a few copies for customer promotion and exhibition which is very helpful to publicize the game in early days.

There are many components of game, Starry Games can provide a safe, good-looking and cost-effective

design layout base on the quantity, size and function of components, also considering of outlook, weight, packaging cost and safety transport for you.

Most of designer’s 3D models are fantastic, but they may not suitable for build the mold and production. Starry Games will do some modification and deepen the details base on customer’s requirement, then make the 3D printing prototype and build the mold. This depending on our engineers' proficiency in 3D software and understanding the molding process, it can cut down the mold cost effectively.